Zip-Lock Bags making machine

Zip-Lock Bags making machine

Our Zipper Bags making machine delivers superior quality products with high precision finishing. With over 10 years of experience in manufacturing zipper bag machines, we provide expertly engineered components for enhanced efficiency and faster production capacity. We also offer five years of complimentary after-sales service and operator training, ensuring you maximize the potential of our machinery.

We offer various packaging options tailored to meet the specific needs and requirements of our clients. Our machine operations are customizable to accommodate unique specifications.

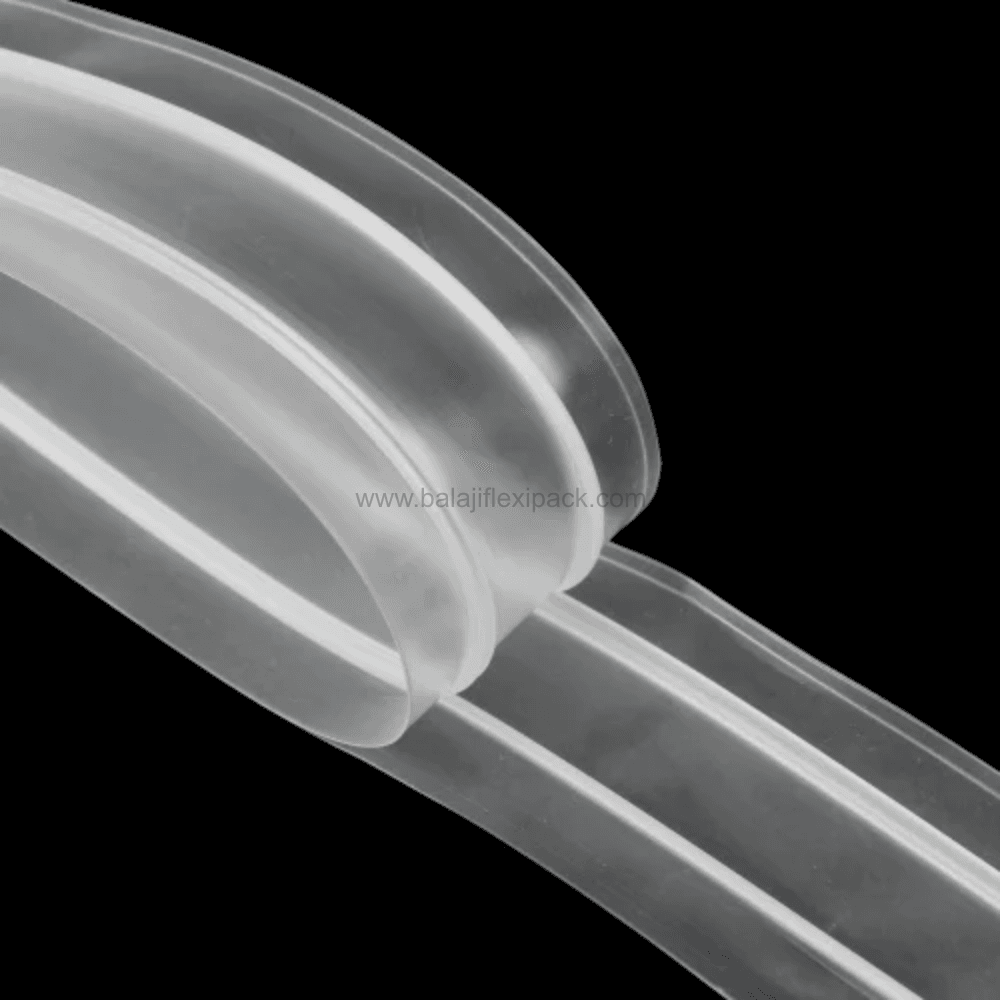

The Zipper Bags making machine can produce tubing from 2″ to 20″ in diameter, with a minimum film thickness ranging from 40 microns to 200 microns. It features up to two colors of online rotogravure printing with corona treatment.

Our complete system includes a high-production main extrusion unit with five separate heating zones, equipped with a 55 mm x 1650 mm screw, and two co-extrusion units with independent speed controllers for superior lock quality. The machine is designed to accommodate different colored male and female locks. A total of 12 air rings are included, along with a high-speed blowing machine for efficient cooling of the tubing, operated by an automatic inflator with sensor control.

We provide 10 molds for tubing sizes from 2″ to 20″, optimized with an industry-leading LLDPE ratio of 70:30 for maximum cost efficiency. Molds up to 9″ support double tubing, generating an output of 15-30 kg/hour at speeds of 600-850 m/hour. The tubing is then processed through a corona treater and a high-precision two-color online rotogravure printing machine, before being wound by a double-station winder.

The material is cut using a high-speed cutting machine with a range of 550 mm to 2000 mm, producing 40 to 200 pieces per minute. This process is controlled via a 7″ LED touch screen and features a static electricity removing stacker for enhanced output. The machine is also equipped with two hole punches, a photocell camera, dancing rollers, and separate knife heating zones synchronized with a PLC controller. Additionally, it includes 2 HP chilling units for cooling and a 2 HP compressor, along with 20 high-strength PP bobbins.

We also offer complementary accessories to enhance functionality.

Our complete Ziplock Bags making machine package includes everything needed for optimal performance and efficiency. With our expertise, you can trust that you’ll get the best results from our machinery.

Specification

- EXTRUSION TOWER

- Tubing Size: 2″ / 50mm upto 20″ / 500mm

- Thickness: 40 Microns / 0.04mm upto 220 Microns / 0.22mm

- Material: LDPE & LLDPE

- Blending ratio: 70:30 / 70% LLDPE : 30% LDPE

- Heating Zones: 5

- Screw size: 55mm X 1650mm

- Output: 15Kgs-30Kgs / Hour

- Speed: 600Mtrs-850Mtrs / Hour

- ROTOGRAVURE PRINTER

- Online Printing: upto 2 Colours

- Side: Both side

- Width: 5mm upto 490mm

- System Support: Dual Servo

- Doctor Blade: Manual or Pneumatic

- CUTTING MACHINE

- Width: 25mm upto 550mm

- Height: 25mm upto 2000mm

- Speed: 40Pcs-200pcs / Min.

- Hole punch: 2 units

- Bobbin station: Dual